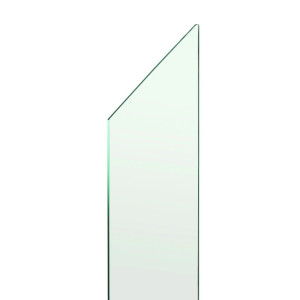

Mica Sheild

- Product Code: Mica Shields

If you are working with steam, hot alkaline, or acidic solutions a mica shield is the best way to protect the integrity of your gauge glass. Over time these liquids will wear down even the toughest gauge glass causing it to eventually crack, or have what looks like a melted appearance. A mica shield helps to prevent corrosion and extends the lifetime of the gauge glass. Moncrieff provides an array of different mica shields in various sizes so you can find the purity, durability, and size that you need for your equipment or application.

Mica shields are divided into different quality groups, as well as different sizes, through a visual inspection. The mica shield that you need depends on the type of process fluid you are working with and your application. Mica shields at the highest quality level, designated by V1, are clear and flat providing the highest level of visibility as well as protection. V1 mica is not obstructed by cracks, air pockets, colours or other factors.

V2 mica shields are slightly coloured, and are considered to be navy-grade quality. The most common choice of grade suitable for most applications, whilst being economical in price are V4 mica shields. These will have more noticeable discoloration, and may contain some air pockets and a slightly wavy appearance. These mica shields still provide suitable protection from steam and alkaline solutions, but have some reduced visibility.

Related Products

Steam Level Gauge - Transparent

SKU: Steam Level Gauge - Transparent

Transparent Level Gauge is perfectly suited for viscous, interface and coloured liquids.With two pieces of glass on opposite sides of the chamber, light passes through the transparent level gauge allo...

Steam Level Gauge - Bi-Colour

SKU: Steam Level Gauge - Bi-Colour

Bi-colour steam level gauge is suitable for high pressure boilers up to 210 bar saturated steam. With a clear red and green liquid and steam reading level indicator, the gauge provides accurate and re...

Process Level Gauge - Transparent

SKU: Process Level Gauge - Transparent

Transparent Level Gauge is perfectly suited for viscous, interface and coloured liquids.With two pieces of glass on opposite sides of the chamber, light passes through the transparent level gauge allo...

Gauge Glass - Reflex

SKU: Gauge Glass - Reflex

These glasses are distinguished by the grooves down the face. The grooves increase the angle of refraction which makes the visibility of the liquid level is much better than when using Transparent Pla...

Gauge Glass - Transparent

SKU: Gauge Glass - Transparent

Clear (smooth on both sides). In order to increase the resistance to operating conditions (pressure, temperature, aggressive environment), transparent glass is typically protected by mica shields on t...

Circular Sight Glass

SKU: Circular Sight Glass

The glass type you require depends on environmental conditions (temperature, pressure, aggressive media.)The basic types of materials used for the manufacture of sight glasses are:soda-lime glass – wi...

Glass Panels

SKU: Glass Panels

As well as our standard range, we also produce custom sizes in a variety of materials, to the size you demand. Any flat shape is possible: Obround, Panels, etc and the other techniques.WATERJET CUTTI...

Tags: gauge glass, mica shield, John Moncrieff, glass protection, industrial equipment, precision engineering, instrument components