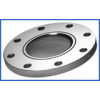

Metal Fused Sight Glass Fittings

- Product Code: Metal Fused Sight Glass Fittings

ADVANTAGES:

- High security

- For sterile applications

VERSIONS:

Metal fused sightglasses for Triclamp fittings:

- for mounting on Triclamp fittings to DIN 32676 / ISO 2852

- available from DN 10 to 300

- available with built-in wiper, series WD (DN 150 to 300)

Metal fused sightglasses for NA-Connect connections:

- for mounting on NA-Connect connections

- available from DN 10 to 100 as well as 1/2" to 4"

Metal fused sightglass flanges for sterile applications:

- for mounting on base flanges to DIN 28117 or similar or on weldnecks with flat face

- available from DN 50 to 200

OPERATING CONDITIONS:

Nominal pressures:

- PN: - 1 to 6 / 10 / 16 / 25 bar (depending on nominal diameter)

- PN: 7 (NA-Connect)

- PN: -1 to 6 bar with built-in wiper

Maximum operating temperatures:

- with ring material 1.4462: - 30 to + 280 °C

- with ring materials 2.4602, 2.4605 and 2.4610: - 60 to + 300 °C

- with built-in wiper series WD: 150 °C

MATERIALS:

Ring: 1.4462, 2.4602, 2.4605, 2.4610

Glass quality: Borosilicate glass to DIN 7080

MANUFACTURED AND TESTED IN CONFORMANCE WITH:

- DGRL 97 / 23 / EG, AD 2000 standards, DIN 7079-1 May 1999

- Materials to VdTÜV specifications and the respective DIN / EN standards

CERTIFICATES:

- To be supplied against extra charge to DIN EN 10204

- Download Data Sheet - Metal Fused Sightglass for Triclamp Fitting (508.08 kB)

- Download Data Sheet - Metal Fused Sightglass for Triclamp Fitting Wipers (351.62 kB)

- Download Data Sheet - Metal Fused Sightglass for NA Connect (385.14 kB)

- Download Data Sheet - Metal Fused Sightglass for NA Connect METACLAMP (293.99 kB)

- Download Data Sheet - Sightglass Flanges Sterile Application (258.26 kB)

Tags: metal fused sight glass fittings, sight glass fittings, process monitoring, industrial fittings, sight glasses, gauge glasses, liquid level indicators, process control, chemical process, manufacturing process, plant equipment, machinery, metal fabrication, welding, glass fusion, durability, reliability, corrosion resistance, high-temperature resistance, pressure resistance, safety, accuracy, visibility